Driving Smart Factories with IoT and Automation

Introduction

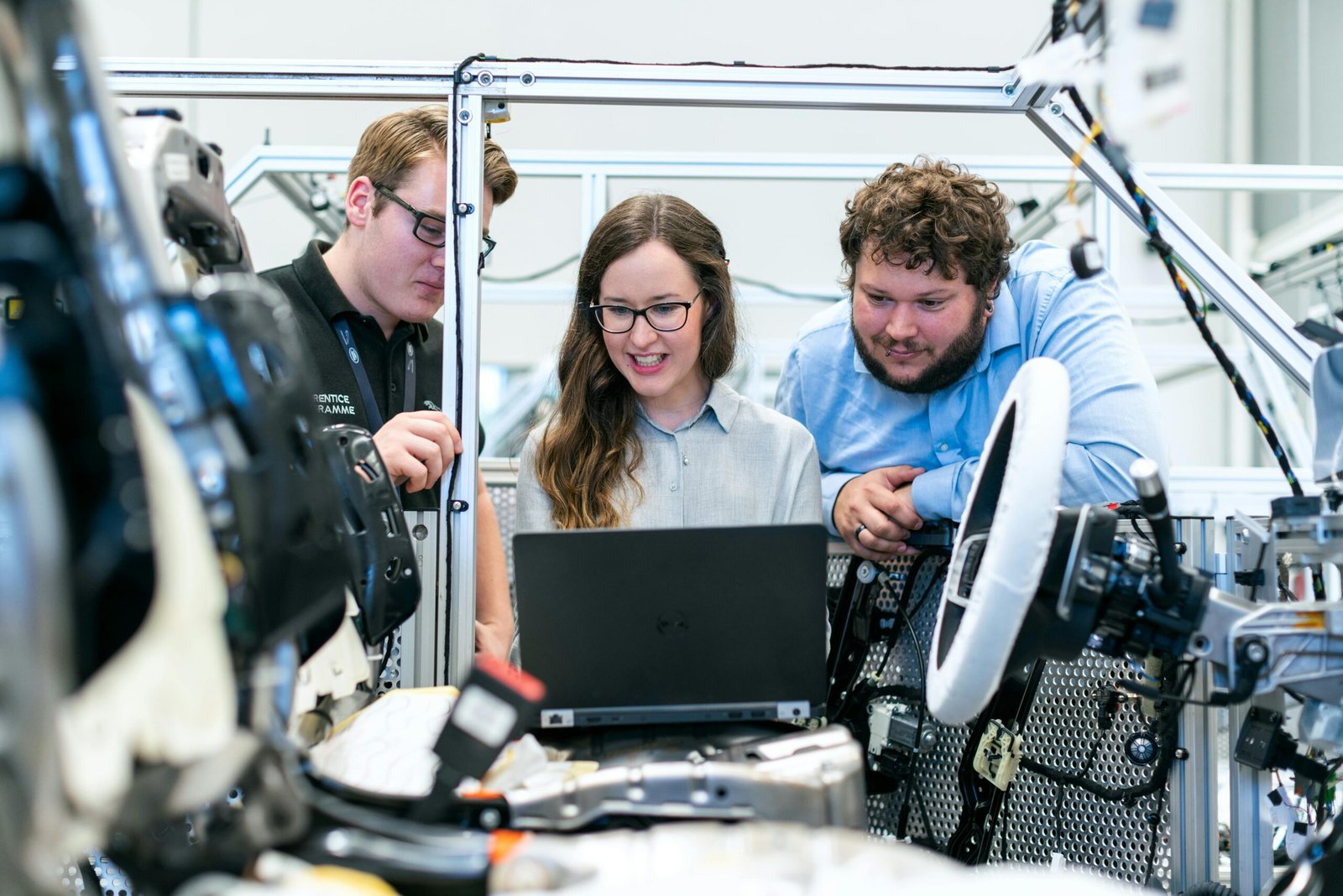

The manufacturing industry is in the midst of a revolution, embracing Industry 4.0 powered by IoT (Internet of Things) and automation technologies. From predictive maintenance to real-time production monitoring, IoT and automation are enabling manufacturers to achieve unprecedented efficiency, reduce costs, and ensure higher product quality. Smart factories, equipped with connected devices and intelligent systems, are transforming the traditional manufacturing landscape into a digitally driven ecosystem.

The factories of the future will have only two employees: a man and a dog. The man will be there to feed the dog, and the dog will be there to keep the man from touching the equipment.

– Warren Bennis (Pioneer in Organizational Development)

Facts and Statistics

- The global IoT in manufacturing market is expected to reach $136 billion by 2030, growing at a 14.5% CAGR.

- 62% of manufacturers are using IoT for predictive maintenance.

- Automation has reduced production errors by 30-50% in leading manufacturing plants.

Adoption of IoT and Automation in Manufacturing

- Predictive Maintenance: Sensors monitor machine health, preventing costly downtime.

- Smart Supply Chains: IoT ensures real-time tracking and inventory optimization.

- Robotics Integration: Automated robotic systems streamline repetitive tasks on assembly lines.

- Digital Twins: Virtual models simulate real-world processes for optimization.

- Energy Optimization: IoT devices monitor and reduce energy consumption across factories.

Challenges Faced Today

- High Initial Investment: Implementing IoT and automation systems can be costly.

- Data Security Risks: Connected devices create potential vulnerabilities for cyberattacks.

- Integration with Legacy Systems: Many manufacturers struggle to modernize older equipment.

- Skill Shortages: A lack of trained professionals limits adoption.

- Scalability Issues: Smaller manufacturers often find it challenging to scale technologies.

How to Overcome These Challenges

- Invest in Scalable Solutions: Begin with modular IoT systems and expand over time.

- Strengthen Cybersecurity: Implement network segmentation, encryption, and endpoint security.

- Enable Workforce Training: Upskill employees to work with connected and automated systems.

- Leverage Cloud Platforms: Simplify integration by using cloud-based IoT solutions.

Solutions by INSAIT Solutions

- IoT-Enabled Predictive Maintenance: Prevent downtime with real-time monitoring.

- Smart Factory Design: Build factories powered by IoT and robotics.

- Digital Twin Integration: Simulate processes for optimization and innovation.

- Automated Quality Control: Ensure defect-free production with AI-powered tools.

- Supply Chain Analytics: Optimize inventory with real-time insights.

Conclusion

IoT and automation are the cornerstones of smart manufacturing, enabling companies to stay competitive in a rapidly evolving market. Overcoming challenges like integration and cybersecurity will be critical for success. With INSAIT Solutions’ expertise, manufacturers can embrace these technologies to achieve operational excellence and drive innovation.